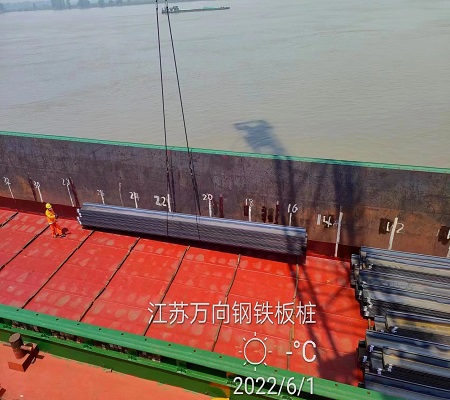

Construction Method of Steel Sheet Pile for Sale

Jul 21, 2020|

Jul 21, 2020| View:1238

View:12381. Construction method of steel sheet pile for sale

Inspection and correction of steel sheet piles used for temporary support of foundation pit shall be inspected for appearance surface defects, length, width, thickness, height, end rectangular ratio, straightness and shape of lock mouth, etc., and the welding parts on the pile that affect the nuclear driving shall be removed (with cutting holes and section defects, reinforcement shall be made). If there is serious corrosion, the actual thickness of the section shall be measured and reduced.

2. Installation of the guide frame

The guide frame is composed of a guide beam and pile, which is divided into the single side and double side in-plane, and common single layer and double layer in height. The project adopts a single-layer and double-sided guide frame. 5 ~ 3.5 m, and 8 ~ 15 m larger than that of sheet pile. The guide frame shall not collide with the steel sheet pile. The pile shall not sink or deform with the driving of steel sheet pile. The proper height of the guide beam should be beneficial to control the construction height of the steel sheet pile and improve work efficiency. The position and height of the guide beam should be controlled by theodolite and level instrument.

3. Selection of pile driving machinery

Steel sheet piles shall be driven by a vibrating hammer. A pile cap is set between the pile hammer and the steel sheet pile to make the impact evenly distributed and ensure that the pile top is not damaged.

4. Steel sheet pile driving

In order to ensure the accuracy of steel sheet pile driving, the screen driving method is adopted. Firstly, hoist the steel sheet pile to the pile insertion point with a crane and insert the pile. When inserting the steel sheet pile, the lock mouth should be aligned. When inserting a piece, the pile cap should be put on and hammered gently. In the process of piling, in order to ensure the verticality, two theodolites are used to control in two directions. In order to prevent the plane displacement of the center of the lock, a plate is set at the lock of the steel sheet pile in the direction of piling to prevent the displacement of the sheet pile. At the same time, the position of each plate is calculated in advance on the purlin for checking and correcting at any time. The steel sheet pile is driven several times, the first from 20m to 15m, the second to 10m, the third to the height of the guide beam, and the fourth time to the design elevation after the guide frame is removed. During piling, the driving position and direction of the first steel plate shall be ensured to ensure the accuracy, and the measurement shall be conducted once every 1 driving.

5. Removal of steel sheet pile

When the foundation pit is backfilled, the steel sheet pile shall be pulled out and reused after trimming. Before pulling out, attention should be paid to the order, time, and hole treatment of the steel sheet pile. When pulling out the pile, certain vibration will be produced. If the pile is pulled out with too much soil, the soil displacement and ground settlement will be caused, which will bring harm to the underground structure already constructed and affect the normal use of buildings, roads, and underground pipelines. The steel sheet pile is removed by vibration hammer and crane. The latter is used for the steel sheet pile which can not be pulled out by the vibration hammer, and the hanger is set on the steel sheet pile, and the crane is used to pull up the steel sheet pile while the vibration hammer is vibrating. The vibration hammer produces forced vibration, which destroys the bond force between the sheet pile and surrounding soil. The pile is pulled out by additional lifting force to overcome the pile pulling resistance. When pulling out the pile, the lock is vibrated with a vibrating hammer to reduce the bond with the pile, and then the pile is pulled out while vibrating. For the pile which is difficult to pull out, diesel hammer can be used to vibrate first, and then vibrate and pull out alternately with vibration hammer. In order to backfill the pile hole in time, when the pile is pulled to a little higher than the base plate, the pulling shall be suspended, and the vibration hammer shall be used to vibrate for several minutes to fill the pile hole produced by pulling pile. The vibration method, compaction method and filling method can be used to timely backfill to reduce the impact on adjacent buildings.