Characteristics of Z shaped steel sheet pile

Jul 16, 2020|

Jul 16, 2020| View:1214

View:1214Characteristics of Z shaped steel sheet pile

1. The section width is large and the pile driving effect is remarkable.

2. Large section modulus.

3. A higher moment of inertia enhances the stiffness of the steel sheet pile wall and reduces the structural deformation.

4. Excellent corrosion resistance.

Advantages of Z shaped steel sheet pile

1. The design is flexible with high section modulus and mass ratio;

2. Higher moment of inertia increases the stiffness of the sheet pile wall and reduces the displacement and deformation;

3. The width is large, which effectively saves the hoisting and piling time;

4. With the increase of section width, the number of shrinkage openings of sheet pile wall is reduced, and its water stop performance is improved directly;

5. Thickening treatment was carried out in the severely corroded parts, and the corrosion resistance was more excellent.

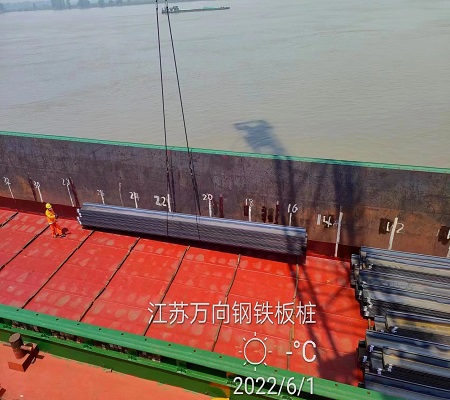

Vibration piling method is adopted for driving a Z-shaped steel sheet pile, and 50t crawler crane and vibrating hammer are used for pile pulling. The construction steps of the Z-shaped steel sheet pile are as follows: setting guide pile frame, clearing Z-shaped steel sheet pile, inserting and driving Z-shaped steel sheet pile, setting internal support, plugging leakage, absorbing mud, hardening base, construction of bearing platform and pier body, pulling out Z-shaped steel sheet pile.

Insert and drive the Z-shaped steel sheet pile. The temporary guide frame is fixed on the drilling platform and the pile hammer is placed under stable conditions. Insert the piles until they are all closed, and then drive them to the elevation in sections and times. The pile insertion sequence starts from the middle of the upstream and is symmetrically driven on both sides until the downstream is closed. The single sheet pile construction method and the screen pile driving method are used in pile driving. First, the sheet piles are driven into the soil one by one. To prevent inclining, after driving a pile, it is welded firmly with the previous one, to prevent inclination and avoid being brought into the soil by the later driven piles. 10-20 sheet piles are inserted into the soil at a certain depth to make the pile driver hammer back and forth. The piles at both ends are driven to the required depth-first, and then the sheet piles in the middle part are driven in sequence. In this way, the inclination and rotation of sheet piles can be prevented.

Plugging. After the Z-shaped steel sheet pile is inserted in place, a circle of color strip cloth can be wrapped around the outside of the pile, and the steel pipe is bound at the lower end of the cloth and sunk into the river bed and pressed with the sandbag. When the mud is sucked in the weir, the color strip cloth can be pressed close to the sheet pile by the external water pressure, which has a certain waterproof effect. The plugging effect is obvious by using cotton sand at the water leakage place of the side lock opening of the sheet pile. In case of deep leakage, the coal slag can be sunk to the leaking place to stop the leakage.